VTech Holdings Limited

42

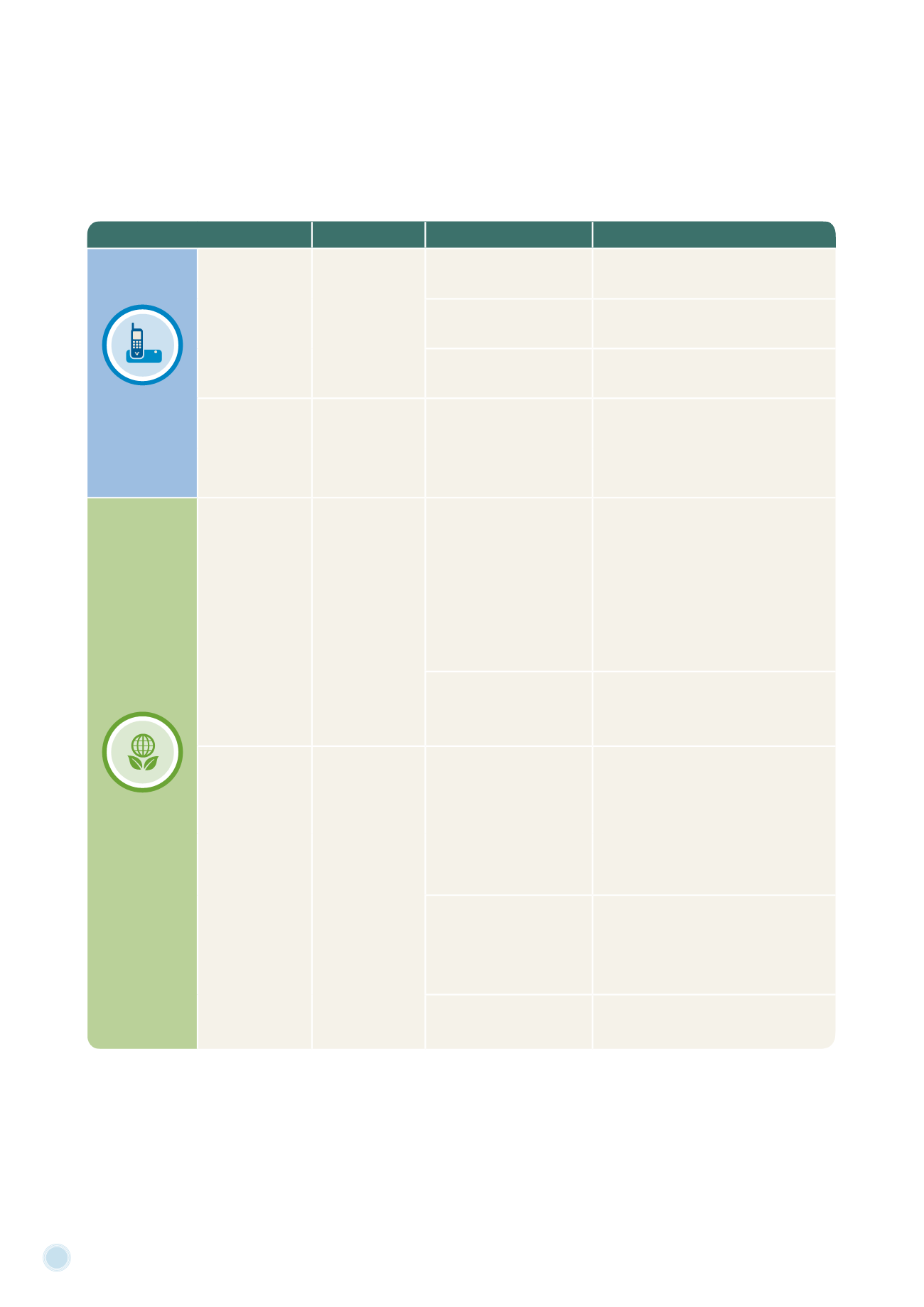

VTECH SUSTAINABILITY PERFORMANCE

Aspects

Approaches

Targets for FY2015

FY2015 Progress Updates

Product

Responsibility &

Innovation

Customer health

and safety

VTech ensures that

its products meet

the highest safety

standards and

contribute to the

protection of our

customers

Zero product recalls, fines

or penalties relating to non-

compliance with regulations

In FY2015, we had no case on product recalls,

fines or penalties relating to non-compliance with

regulations.

Increase sales by 2% for health

and safety related products to

customers

In FY2015, the sales of our health and safety

related products increased by 46.5% compared

with FY2014.

Develop innovative concepts

which enhance the health and

safety of the customers

We have incorporated more health and safety

features to our TEL products, such as voice

booster and big button.

Product

design

Incorporate

sustainability

concepts into

product design

to reduce carbon

footprint and

resources used

Undertake Life Cycle Analysis

(LCA) for 2 key products to

reduce the carbon footprint

throughout the product life cycle

In FY2015, we completed the LCA for the phone

models CS6829 and CS6629 and reduced the

carbon footprint by 40%.

We also completed the LCA for toy models

151500 and 61320 and reduced the carbon

footprint by 23%.

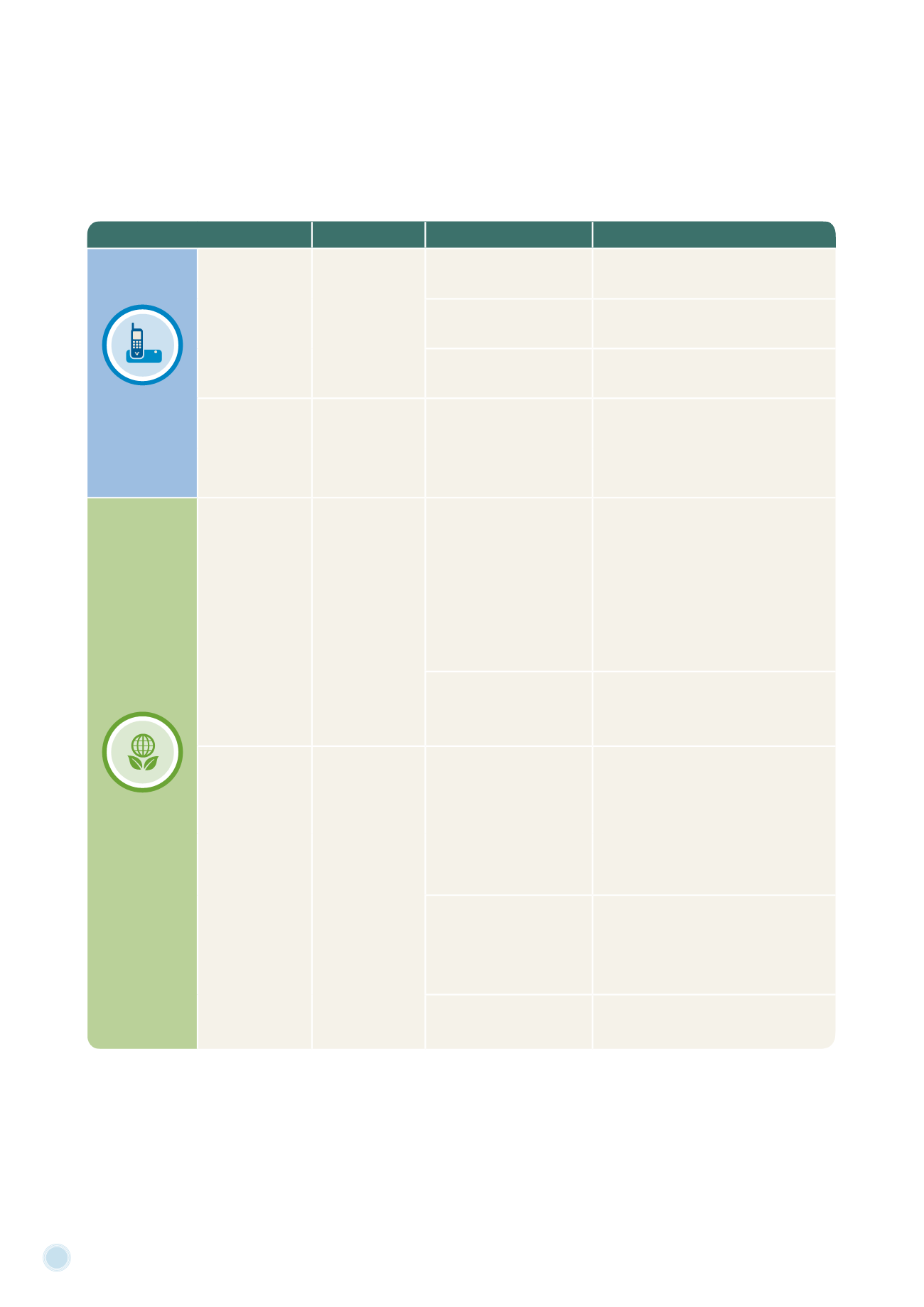

Environmental

Protection

Energy

Reduce the

energy used in our

manufacturing and

living facilities

Reduce electricity consumption

(kwh) per sales by 4% against

FY2014

In FY2015, the total electricity consumption

(kwh) per sales increased by 5.4% compared

with FY2014. It was mainly attributable to

our continuous improvement programmes in

the living areas of the factories, including the

upgrade of the air-conditioning systems at the

dormitories and canteens.

Our electricity consumption per production

output in the manufacturing facilities, however,

had successfully reduced by 5.4% compared

with FY2014 due to our continuous efforts on

improving the energy efficiency.

Phase-out the use of diesel in all

static appliances

In FY2015, our total diesel usage had decreased

by 47.8% which resulted in a reduction of

Scope 1 carbon emissions by 21.8% compared

with FY2014. We will continue to replace diesel

with natural gas at the manufacturing sites.

Carbon emissions

Reduce GHG

emission

Reduce GHG emissions by 2%

against FY2014

Our GHG emissions increased by 3.2%

compared with FY2014. It was mainly

attributable to our continuous improvement

programmes in the living areas of the factories,

including the upgrade of the air-conditioning

systems at the dormitories and canteens.

Our GHG emissions per production output,

however, had successfully reduced by 3.6%

due to our continuous efforts on improving the

energy efficiency.

Undertake feasibility study

for solar photovoltaics at one

manufacturing site

Our Resource Efficiency and Conservation Team

undertook a study on solar photovoltaics (PV) at

manufacturing facility. Due to the area constraint

at the rooftop of the production buildings, the PV

panels cannot be installed on the rooftop. The

team is now working with local PV suppliers to

seek for alternatives.

Collect data for refrigerant gas

releases to complete Scope 1

reporting

We had started to collect the refrigerant usage of

all manufacturing sites in FY2015.

FY2015 Targets and Progress Updates