Sustainability Report 2017

41

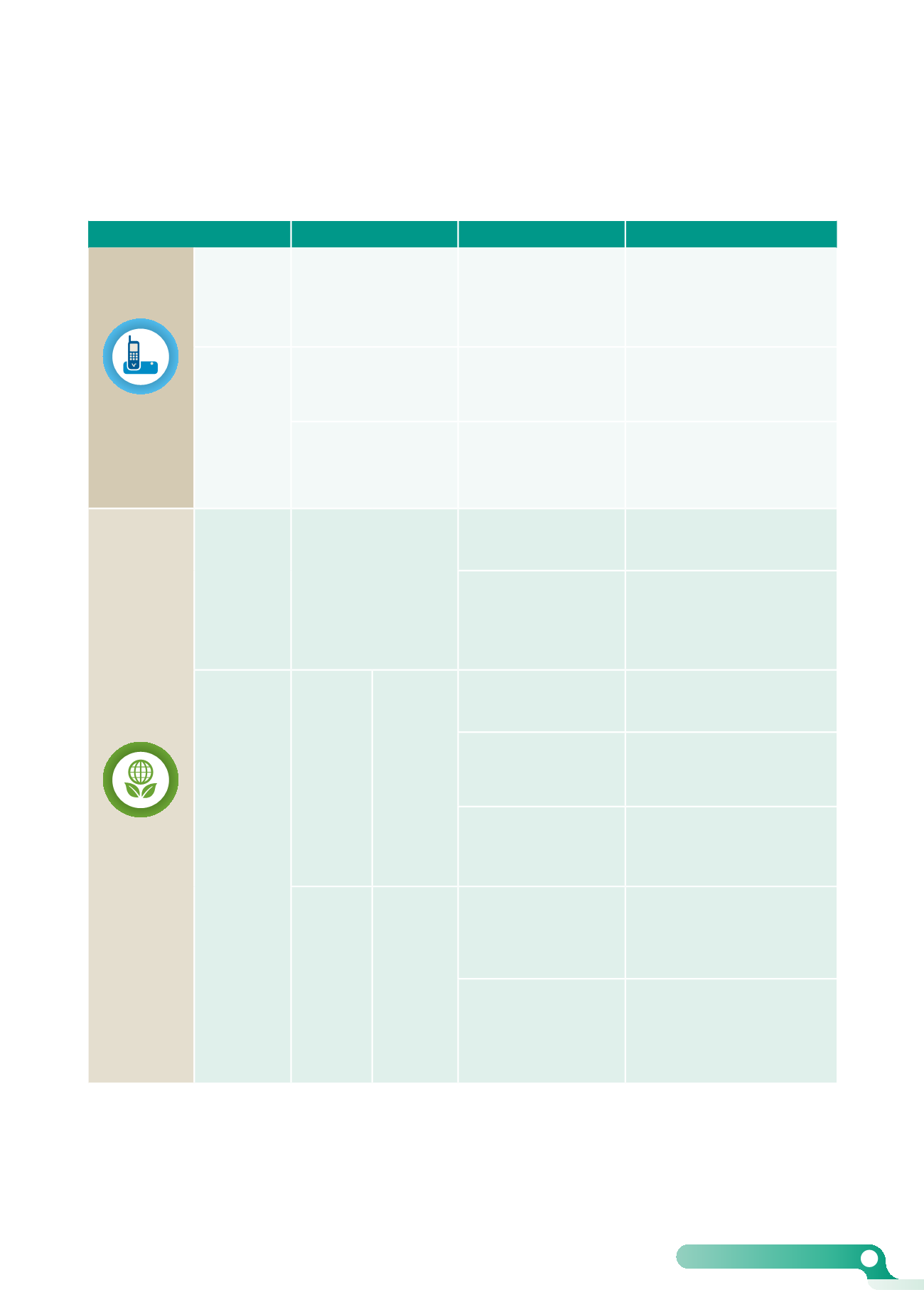

FY2017 Targets and Progress Updates

Strategy Themes

Approaches

Targets for FY2017

FY2017 progress update

Design for

People

Continue to use our

technological expertise to

design and provide products

to enhance the well-being of

our customers and benefit the

society

Increase the total sales of health

and safety products by 10%

compared with FY2014

Health and safety products sales grew by

135.6% compared with FY2014.

Design for

Excellence

Continue to ensure that all

products are compliant with the

international quality and safety

standards

Zero product recalls, fines

or penalties relating to non-

compliance withregulations

In FY2017, we had no case on product

recalls, fines or penalties relating to

non-compliance with regulations.

Follow the Life Cycle Analysis

(LCA) Guideline , aiming to

reduce the carbon footprint

in each new generation of the

products

Undertake LCA analysis for 2

key products in TEL products

and ELPs to reduce the carbon

footprint throughout the product

life cycle

We had performed LCA on one new TEL

product and one ELP.

High

Performance

Production

Chain

Implement more low cost

automation projects and further

strengthen the operational

management to improve the

production efficiency and

productivity

Increase production output per

worker by 8% compared with

FY2014

Production output per worker increased

by 31.5% compared with FY2014.

Continue to monitor the

progress of our energy

saving programmes and

conduct weekly patrols to

eliminate unnecessary energy

consumption

We had carried out various energy

reduction projects in FY2017, such as

installing air compressor and remodelling

blowguns.

Green

Manufacturing

Energy

Consumption

and Carbon

Emissions

Reduce

energy

consumption

and thus

the carbon

emissions

Reduce Greenhouse Gas (GHG)

emission per production output

by 8% compared with FY2014

GHG emission per production output

decreased by 15.9% compared with

FY2014.

Continue to upgrade the

ventilation system and perform

re-layout of the air conditioning

ducts of the production floors

After a thorough study, it was recognised

that more electricity can be saved by

installing the air compressor.

Continue to adopt the hydraulic

servo control technology in

our existing injection moulding

machines

We continue to adopt the hydraulic

servo control technology and expect to

complete the project within 5 years.

Water

Reduce water

consumption

and improve

effluent

treatment

Continue to promote water

saving campaigns throughout

the Company

In FY2017, with our continuous effort

to promote water saving campaign

throughout the Company, our total water

consumption decreased by 19.2%

compared with FY2014.

Install water recovery system

and low-flow taps in canteens

Water recovery system and low-flow

taps were installed at the canteen of ELP

factory. We had also installed 2 rainwater

harvest systems at two manufacturing

sites for reducing the consumption of

freshwater.

VTECH SUSTAINABILITY PERFORMANCE

Product

Responsibility &

Innovation

Environmental

Protection