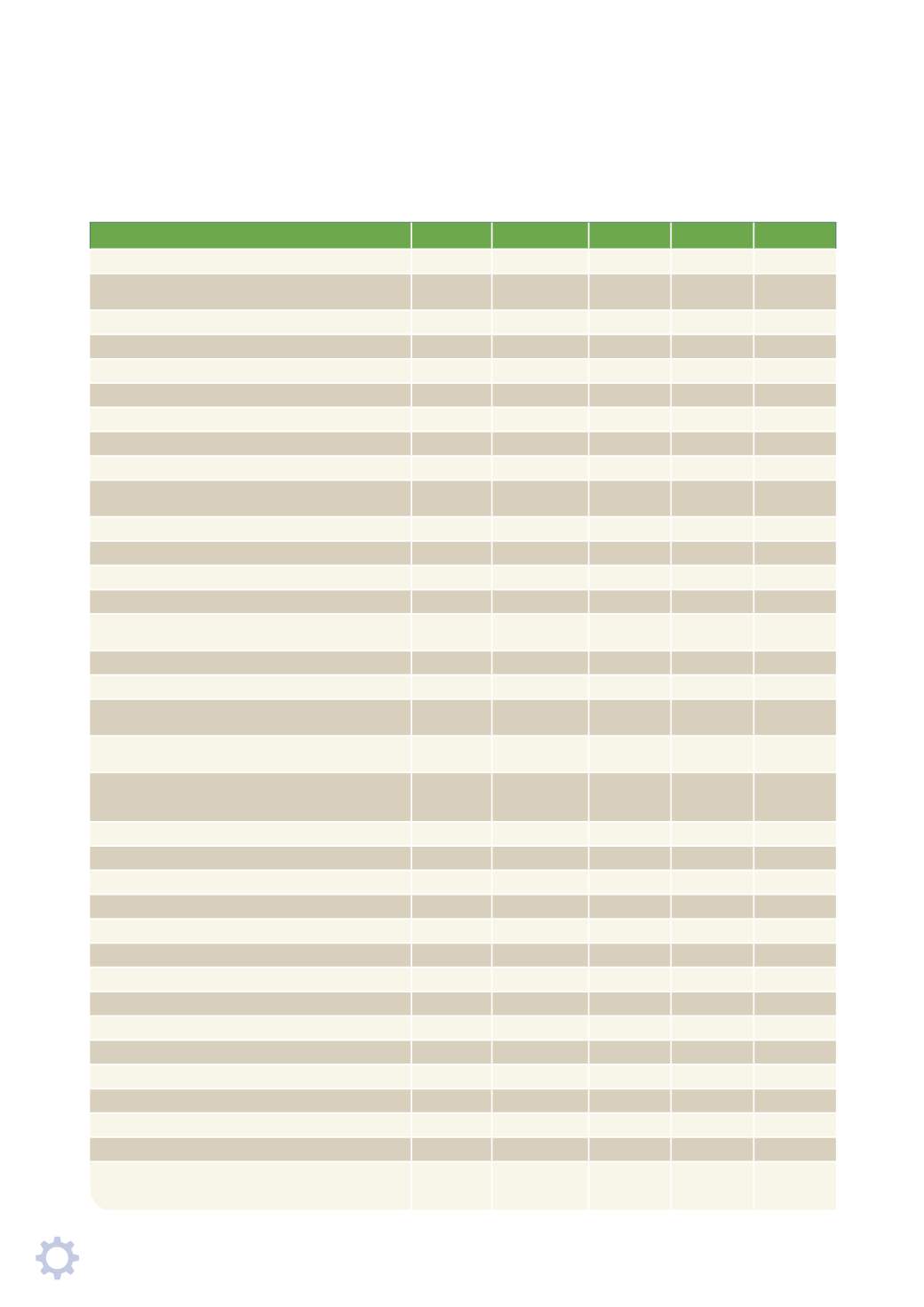

VTech Holdings Limited

44

VTECH SUSTAINABILITY PERFORMANCE

Items

G4 Indicator HKEx Indicator

FY2014

FY2015

FY2016

Portion of senior management hired from local community

9

G4-EC6

98%

98%

98﹪

Proportion of spending on local suppliers at significant location of

operation

G4-EC9

B5.1

89%

94%

94﹪

Material used by weight or volume (1000Tonnes)

G4-EN1

79.3

86.1

86.0

Energy use

1

(GJ)

G4-EN3

A2.1

587,365

605,227

568,648

Energy from Diesel

1

(GJ)

G4-EN3

A2.1

7,218

3,768

1,047

Energy from Natural Gas

1

(GJ)

G4-EN3

A2.1

41,583

39,180

35,050

Energy from Electricity

1

(GJ)

G4-EN3

A2.1

538,564

562,279

532,551

Energy use

1

per production output (GJ per 1,000 unit)

G4-EN5

A2.1

4.753

4.526

4.280

Energy from Diesel

1

per production output (GJ per 1,000 unit)

G4-EN5

A2.1

0.058

0.028

0.008

Energy from Natural Gas

1

per production output (GJ per 1,000

unit)

G4-EN5

A2.1

0.336

0.293

0.264

Energy from Electricity

1

per production output (GJ per 1,000 unit)

G4-EN5

A2.1

4.358

4.205

4.008

Electricity used (Kwh)

G4-EN3

A2.1

149,601,160 156,188,568 147,930,737

Electricity used per production output (Kwh per 1,000 unit)

A2.1

1,211

1,168

1,113

Water comsumption

2

(meter cube)

G4-EN8

A2.2

2,503,745

2,415,255

2,033,109

Water comsumption

2

per production output (meter cube per

1,000 unit)

A2.2

20.3

18.1

15.3

CO

2

emission Scope 1

3

(tonne of CO

2

e)

G4-EN15

A1.1, A1.2

4,750

4,002

3,851

CO

2

emission Scope 2

3

(tonne of CO

2

e)

G4-EN16

A1.1, A1.2

100,613

105,043

99,489

CO

2

emission Scope 1

3

, per production output (tonne of CO

2

e

per 1,000 unit)

G4-EN18

A1.2

0.038

0.030

0.029

CO

2

emission Scope 2

3

per production output (tonne of CO

2

e per

1,000 unit)

G4-EN18

A1.2

0.815

0.786

0.749

Monetary value of significant fines and total number of non-

monetary sanctions for non-compliance with environmental laws

and regulations

G4-EN29

0

0

0

Injury

4

cases

G4-LA6

B2.1

113

115

84

Lost Hours

5

G4-LA6

B2.2

11,885

10,756

8,256

Injury rate per employee

6

G4-LA6

0.004

0.004

0.003

Injury rate per employee

6

– male

G4-LA6

0.005

0.005

0.005

Injury rate per employee

6

– female

G4-LA6

0.002

0.003

0.001

Absentee rate

7

(%) – overall

G4-LA6

0.4%

0.3%

0.3%

Absentee rate

7

(%) – male

G4-LA6

0.3%

0.2%

0.2%

Absentee rate

7

(%) – female

G4-LA6

0.5%

0.4%

0.4%

Average training hours per employee

G4-LA9

B3.2

19.3

22.7

29.1

Average training hours per employee – male

G4-LA9

B3.2

19.3

22.5

28.8

Average training hours per employee – female

G4-LA9

B3.2

19.3

23.1

29.5

Average training hours per employee –management

8

staff

G4-LA9

B3.2

8.1

8.4

7.9

Average training hours per employee – professional/engineer

G4-LA9

B3.2

6.7

9.7

14.2

Average training hours per employee – staff & workers

G4-LA9

B3.2

21.2

24.9

31.8

Incidents of non-compliance with regulations on health and safety

impact on products that result in a significant fine, penalty or

warning

G4-PR2

0

0

0

Company Performance and Data