Sustainability Report 2017

21

proactively on all reported cases in a

timely manner by carrying out reviews,

evaluations and investigations, followed

by immediate corrective or preventive

actions to satisfy our customers’

preferences.

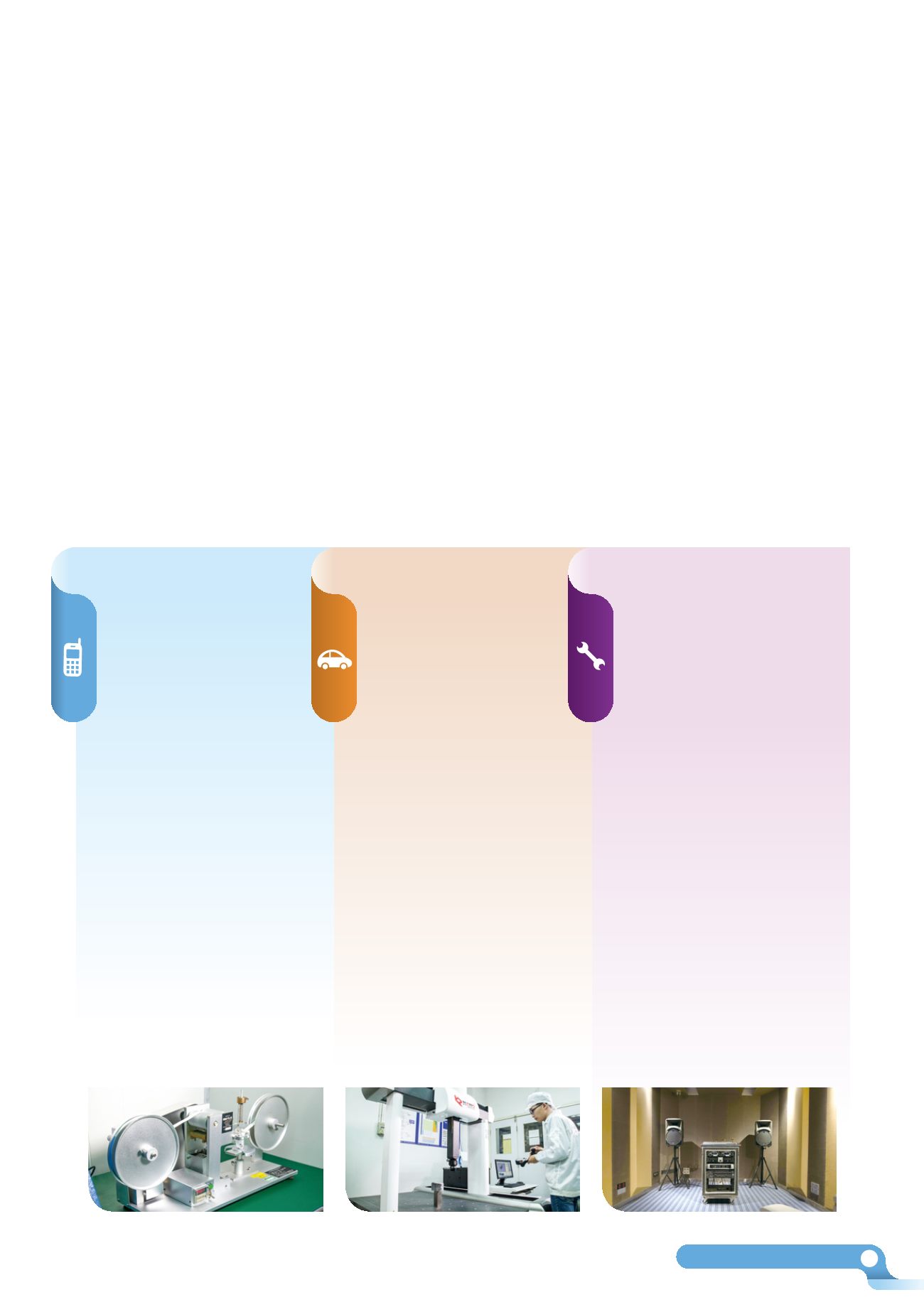

VTech Quality Laboratories

To improve the quality, durability and

performance of our products, we have

set up our in-house product testing

laboratories (labs) at the manufacturing

sites of our three product lines. All our

products must go through reliability

tests during different design stages. The

comprehensive tests provide data for

our engineers to improve the quality and

reliability during the stages of production,

transportation, storage and throughout

the intended product life cycle under a

wide range of use conditions. Ongoing

reliability test is also conducted during

the mass production stage on a

sampling basis to detect any anomalies

or changes that may occur in the design,

supply chain or production process

that adversely changes field reliability

performance of our products.

The reliability lab of TEL products is

designed based on the international

requirements and standards, and our UL

Safety Lab is the first telecommunication

manufacturing facility to comply with

UL 60950 in Guangdong. Our in-house

physical and chemical laboratory of ELPs

is a China National Accreditation Service

(CNAS) certified laboratory for ASTM

F963 & EN71-1 (specific test items)

standards since 2011 and complies

with ISO 17025 standards. Equipped

with advanced testing instruments, our

in-house chemical laboratory is also

able to test specific chemicals such as

heavy metals and phthalates. Samples

of our VTech products are also sent to

independent safety testing labs before

they are brought to market to ensure

that they meet the highest levels of

international and local quality and safety

standards.

TEL Products Test Labs

Compliance Lab

• Signal Performance

• Alerting

• Transmission Characteristics

• Environmental Considerations

• Caller Identity (CID) Test

Reliability Lab

• Salt Fog Test/Autoclave Test

• Carton Vibration Test/Carton Drop

Test/Carton Stacking Test

• Unpacked Drop Test

• Waterproof Test/Surface

Temperature/Battery Life

• ESD Test/Energy Star/CEC

• Charge-contact life/Keypad Life/

Coil Cord Life

• Silkscreen & Painting Abrasion Test

UL Safety Lab

• Stress Relief Test

• Drop Test

• Impact Test

• Over-voltage Test

• Hi-pot Test

• Humidity Test

• Steady Force Test

• Acoustic Test

ELPs Test Labs

Reliability Lab

• Wire Bending Test

• Keyboard Life Test

• Component Life Test

• Storage Test

• Operating Temperature

• ESD Test

• Transportation Test – Vibration Test

• Transportation Test – Carton Box

Drop Test

• Sound Test

• Tension Test

• Torque Test

• Impact Test

• Compression Test

Chemical Lab

• Pb, Hg, Cr & Cd on Electronics

Components

• Heavy metals (soluble & total

contents) on Surface Coatings and

Substrates

• Phthalates & Organostannic

Compounds Test on Surface

Coatings and Substrates

• Chromium III & VI Analysis on

Surface Coatings and Substrates

CMS Test Lab

Measurement & Reliability Lab

• Temperature Humidity Environmental

Stress Test

• Vibration Test

• Salt Spray Corrosion Test

• Connector Insertion Cycling Test

• Abrasion Test

• Switch On-Off Cycling Test

• XRF Spectrum Analysis

• Melt Flow Index Analysis

• Automated 3D Dimension

Measurement

• Height Measurement

• Optical Microscopy Analysis

• RCL Measurement

• IV Curve Analysis

• Signal Analysis

• Quartz Oscillator Test

• Color Spectrum Analysis

• X-Ray Imaging Analysis

• Water Ingress Test

• Wire Load Swing Test

Abrasion Test

Automated 3D Dimension Measurement

Audio Lab