VTech Holdings Limited

VTECH SUSTAINABILITY ACTIVITIES

22

Design for Environment

VTech’s products are designed to

minimise our environmental impacts

throughout the whole product life

cycle from cradle to grave. With the

compliance of RoHS2 and REACH

standards, we aim to use minimum

permitted hazardous substances

and chemicals in all ELPs and TEL

products. We also follow the LCA

principle from the beginning of the

product design to different stages of

production chain. Our designers and

engineers are required to follow the

requirements on the LCA checklist

to select a more eco-friendly product

and packaging materials, reduce

the use of materials and energy,

maximise the use of reusable items

and avoid disposing of recyclable

materials to landfill during the product

development stage. We initiated

our “Every Component Counts”

principles since 2008 and we have

made continuous improvements

in the reductions of material and

components usage in our products.

Through our “Every Component

Counts” programme, our designers

and engineers also make suitable

adjustments for components and

material reductions. In recent years,

we have continued to embed the

principle of “Compact Design” in our

packaging design, choosing more

environmentally friendly packaging

materials and reducing the weight of

materials used for all VTech products.

For example we chose to use PP

(Polypropylene) plastic instead of

ABS (Acrylonitrile Butadiene Styrene)

plastic for some of our ELPs and used

100% recyclable cardboard as the

packaging materials for all ELPs.

We continue to incorporate

eco-design principles from the

manufacturing phase of the

production life cycle to the product

usage in the end user’s home. Every

year we conduct LCA practice for

our key products to compare the

carbon footprint between the old

and new models, and ensure that

there is continuous reduction in

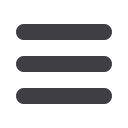

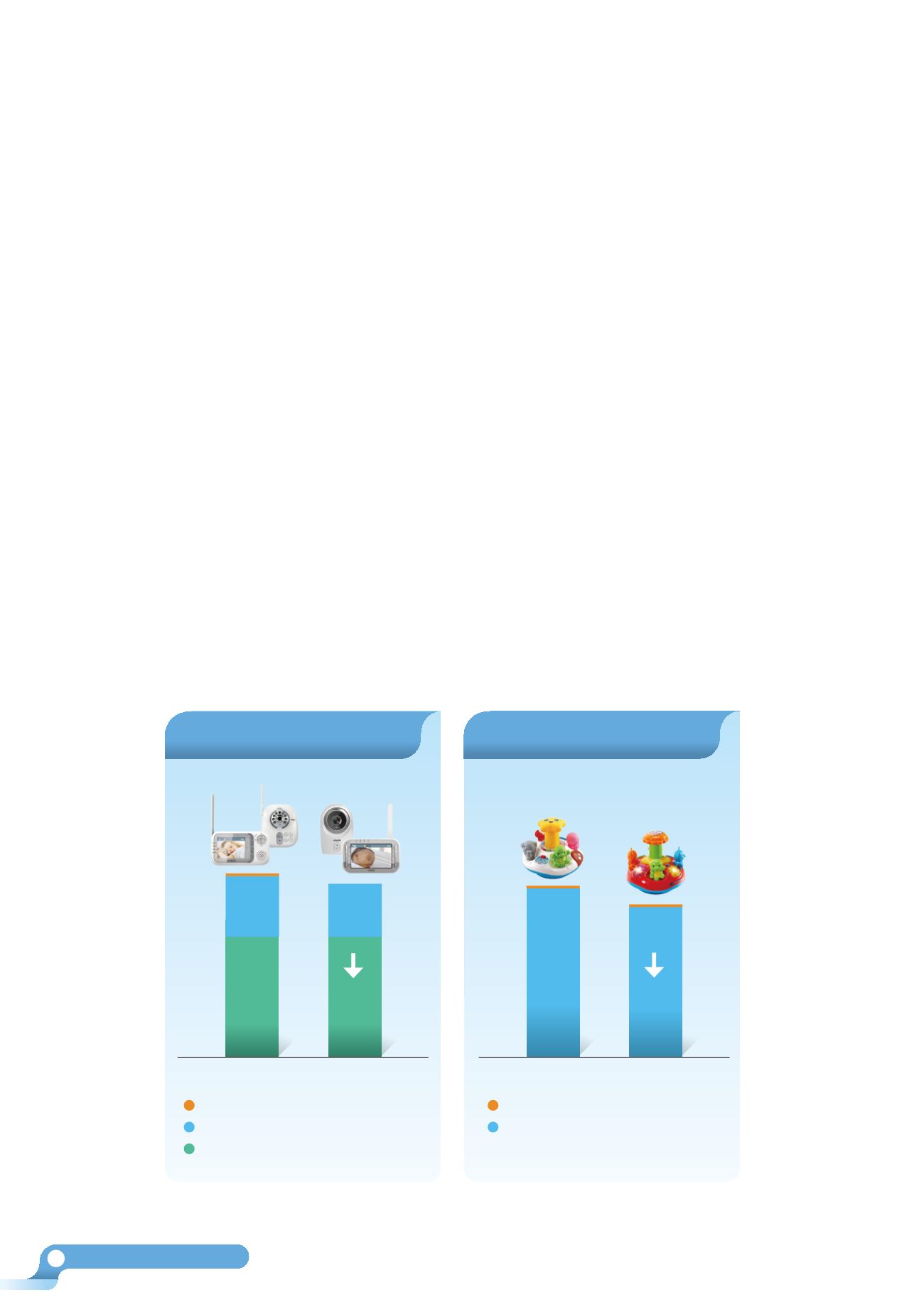

carbon footprint of the new model. By

embedding the eco-design principles

and with continuous reduction in

plastic materials and components

usage, the carbon footprints of the

following two new ELP and TEL

models have reduced 11% and 6%

respectively compared with the old

generation.

We have also successfully launched

our first TEL product that uses

waterborne paint. Compared to

the traditional solvent base paint,

the application of waterborne paint

substantially reduces the usage

and emission of Volatile Organic

Compounds to the atmosphere

both in the product itself and in

the manufacuring process, which

also improves our productivity and

air quality at our workplace. This

provides our customers with more

eco-friendly choices.

6%

Old Model

New Model

11%

Old Model

New Model

Other stages (logistic, disposal)

Manufacturing

Other stages (logistic, disposal)

Manufacturing

Use Phase

VTech Product Carbon Footprint

Comparison of Baby Monitor

VTech Product Carbon Footprint

Comparison of Infant Toys